November, 2020

In times of a pandemic, it becomes clear how important globalization and worldwide logistics are for companies. Despite all this, we want to think proactively into the future and further advance logistics. Today’s article therefore focuses on our two-week pilot at syncreon. The question you might ask is: What is a pilot?

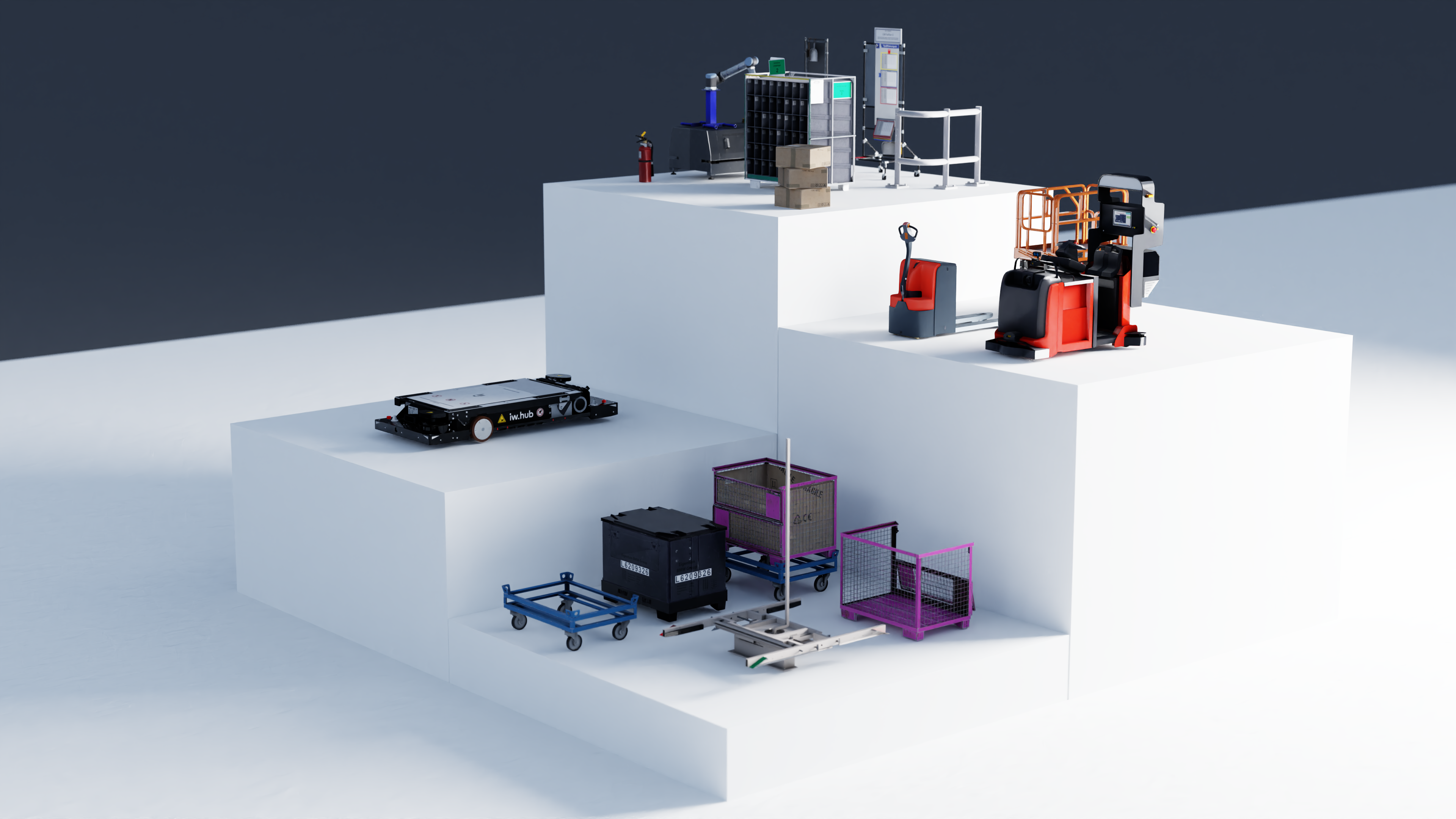

Before we sell our iw.hubs to companies, we first use two devices as a pilot project to test the use case and see how the iw.hubs can be integrated into the company’s processes. In the middle of 2020, we successfully deployed such a pilot at syncreon in Neutraubling.

The syncreon Group is a company that provides specialized logistics, operational excellence, and value-added solutions in warehouse management, inbound to manufacturing, export packing, and transport management. syncreon is a global player in intralogistics for industrial company’s worldwide. The location in Neutraubling has been opened in 2003, where car parts for the BMW Group are being packed to be ready to be shipped to global destinations including China, USA, Brazil, or Thailand.

In Neutraubling, the iw.hubs are used to support the employees in their daily work, so that they can concentrate on their main tasks while their secondary workload is reduced. Furthermore, the processes within the company are becoming standardized with the help of our equipment. At the beginning of such a pilot, the iw.hubs are first implemented and made operational. To do this, one of our employees uses the device to run a one-time scan of the entire factory floor or the routes that the hub has to take, and uses the intelligent system to create a virtual map of the environment that is stored in the cloud. This map is the basis for the route calculation of the robots, but is constantly adapted and optimized with the help of on-board algorithms.

At syncreon, our modular platform is used for the reception and transport of empty and full goods, where our robots bring goods to designated areas or parking spaces; from where it is then transported out of the warehouse. These processes already functioned autonomously on the second day — and by the end of the first week, the missions they received were 100% successful.

The process within the factory hall is carried out in such a way that the goods are first delivered by truck, followed by the unloading of the material into the block storage. Subsequently, a syncreon employee presses the Call Button and the iw.hubs start their work order — the transport of empty and full goods. Once the mission is complete, the packaged goods are brought to a truck on pallets and are ready to be shipped to the respective countries.