Build your automated future with AnyFleet

Why

How

WHat

Why

How

WHat

KEY USPs

AnyFleet at the forefront of industrial automation and fleet management

Implementation

Fast and straightforward implementation of a user-friendly fleet management solution tailored to your needs.

Power of Choice

Configurable services and devices that fulfill your operational needs based on the subscription model that suits you.

Scalability

Software-as-a-Service (SaaS) solution integrating multiple robot types and connected devices to ensure scalability and enable your automation transformation.

Standards

Standardized communication interface, e.g. VDA 5050, to support heterogeneous fleets, allowing you to control and monitor all your robots on one platform.

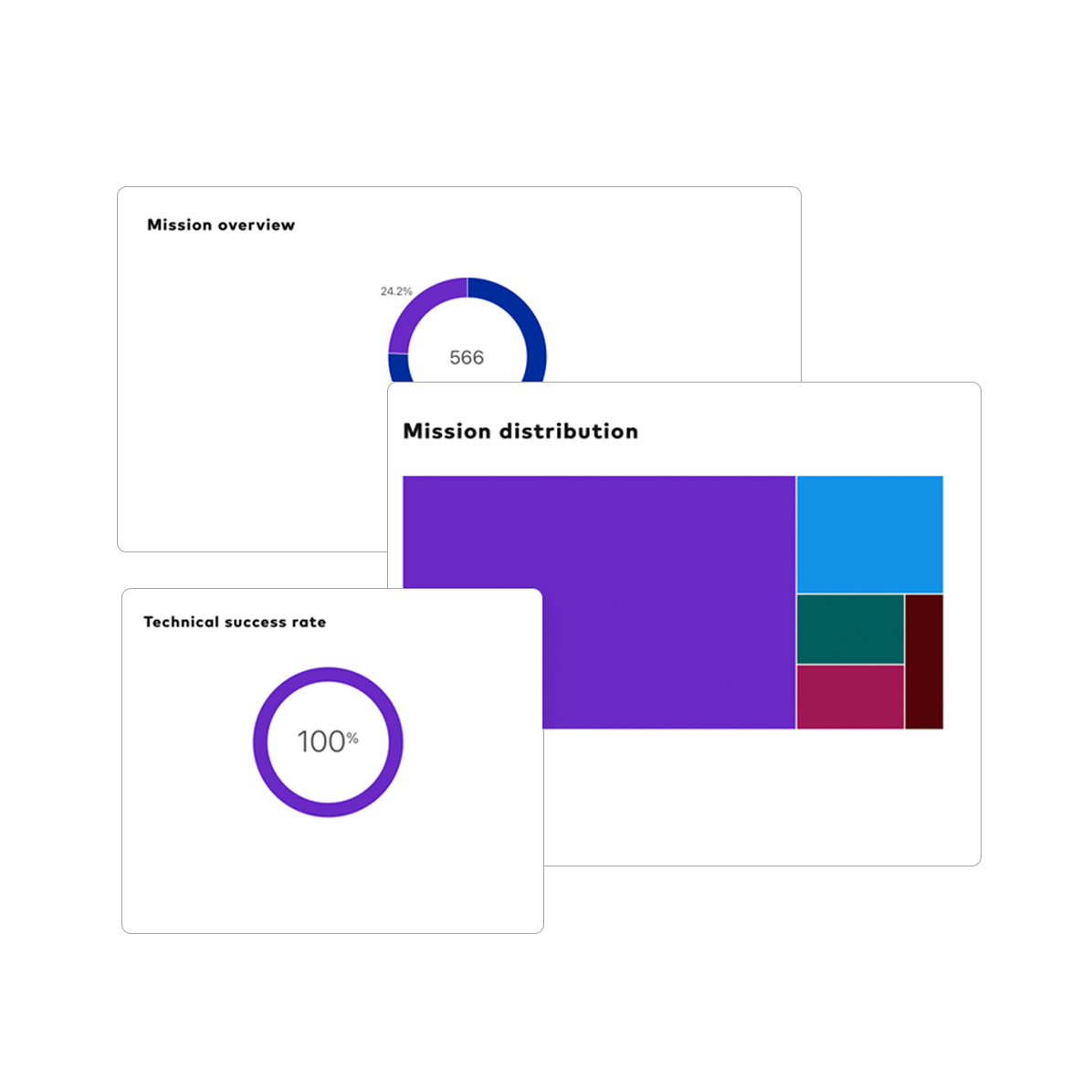

Data Analytics

Dashboards to provide you with actionable insights and enable your data-driven decision-making.

AI-Powered

AI-enabled fleet management system for efficient execution and continuous optimization.

Fleets & Transports

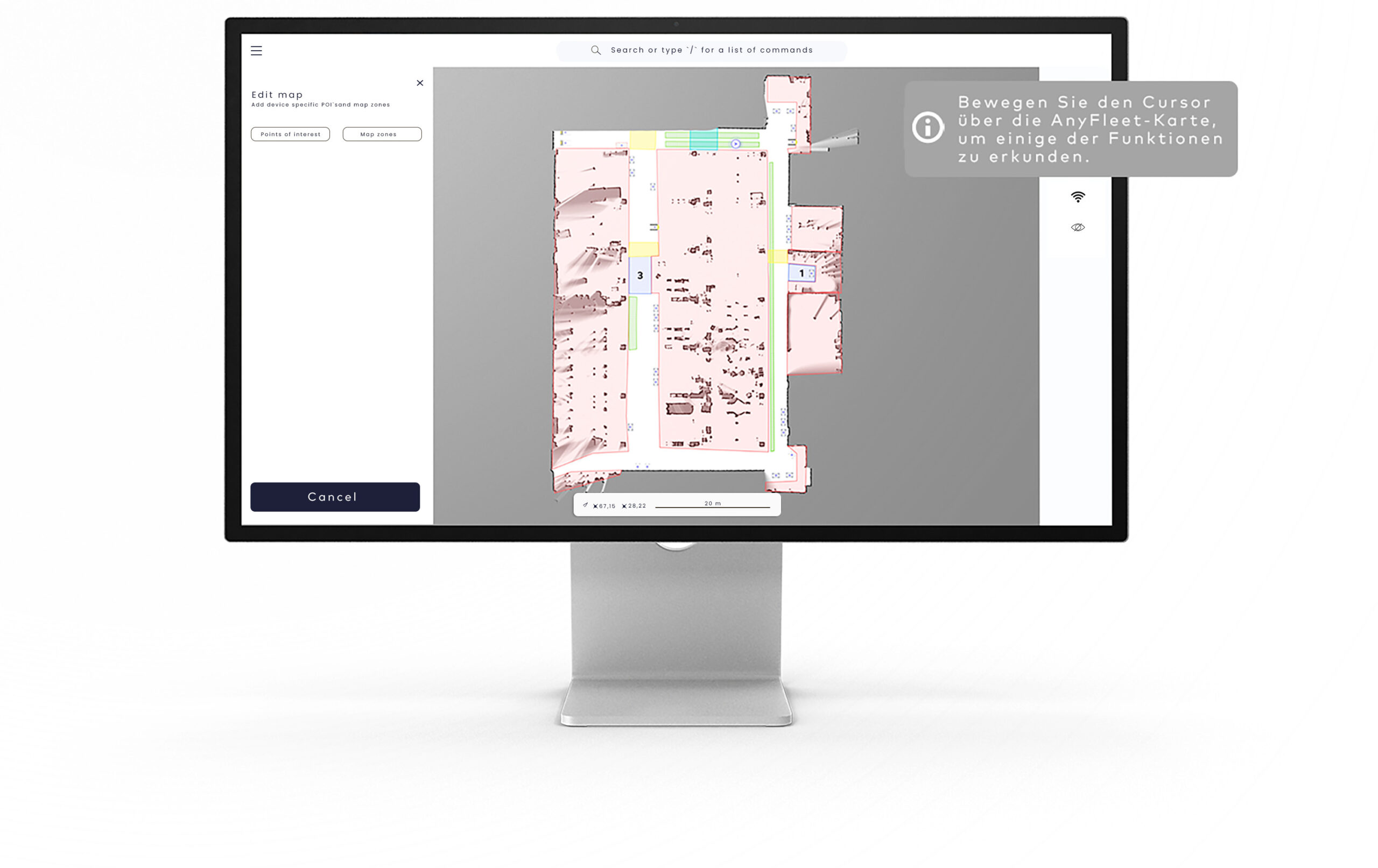

AnyFleet users create automations that mirror their material flows and encode environmental constraints on an interactive map view through zones and points of interest.

AnyFleet connects to mobile robots from different vendors and orchestrates transports in your industrial facility. AnyFleet’s core services include task assignment to pick the right robot for the right task, traffic management to avoid congestion and optimize routes, and task scheduling to plan mission execution.

Interfaces

& Peripheral Devices

AnyFleet integrates with your environment by onboarding your industrial IoT devices (e.g. alarms, sensors, doors) and interfacing with your ERP and WMS systems.

Users can configure rules to link devices and connected systems to AnyFleet missions in real time. In addition, missions can be triggered and monitored programmatically through application programming interfaces, APIs.

Advanced Monitoring

& Reporting

Through interactive map visualization, users can track active missions, robots’ states and positions in real time. Users can also easily modify the map configuration to cope with changing environments.

AnyFleet is built to provide transparent, in-depth analytics on fleet performance.

This is done by collecting and aggregating data from all devices and displaying crucial key performance indicators, KPIs, related to active and past missions. AnyFleet dashboards allow users to extract actionable insights in order to improve their processes.

Explore the Map yourself

Speed Limit

Robots drive through the zone at

a defined maximum speed.

No Replanning

Robots are not allowed to avoid

obstacles within this zone.

Restricted

Robots are not allowed to enter

this zone.

Overlapping Zones

Within the overlapping zones, the

appropriate restrictions apply.

Limited Capacity

Only a defined and limited number

of robots are allowed to enter the

zone at the same time.

Directed

The robots drive through the

zone in a specific direction.

Point of interest (POI)

POIs are used to pin specific locations on the map (e.g waiting point, dolly, charger).