Meet your new team player

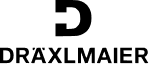

Intelligent, flexible, and robust – iw.hub combines industry-leading computing power and proven hardware to automate intralogistics workflows in industrial environments.

iw.hub

Why

How

WHat

Why

How

WHat

KEY USPs

iw.hub as your newest

most reliable team player

Implementation

Smooth integration with no additional infrastructure required and with limited human supervision

Safety

Safe operation around humans in industrial areas ensured by industry standard regulations, including CE certification and ANSI RIA15.08

Operability

Operators are equipped with a set of tools enabling supervised autonomy

Reliability

Combination of industry-proven hardware and adaptive software, ensuring reliable performance in complex environments, with a high operational efficiency

Flexibility

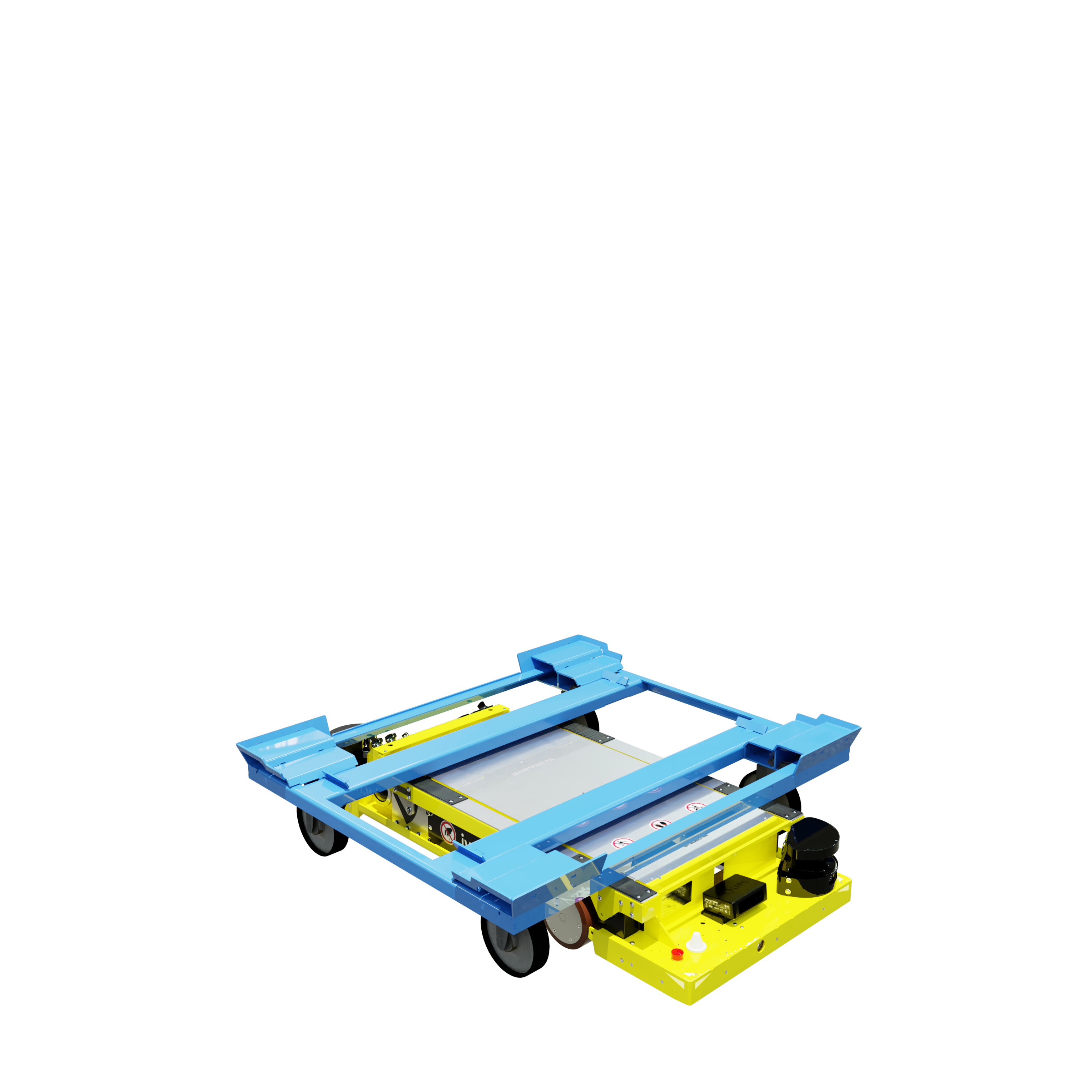

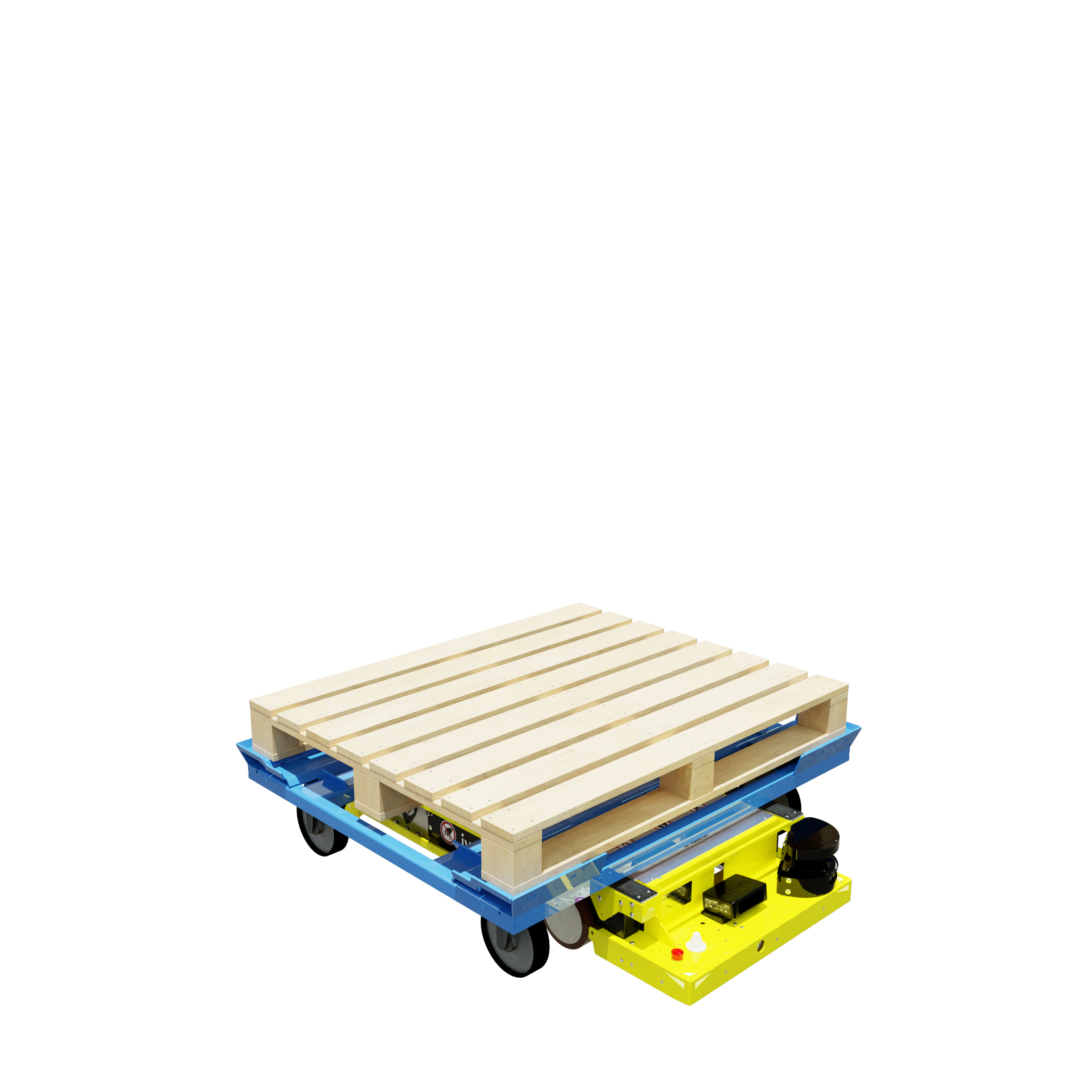

Use of various load carriers possible depending on individual use cases

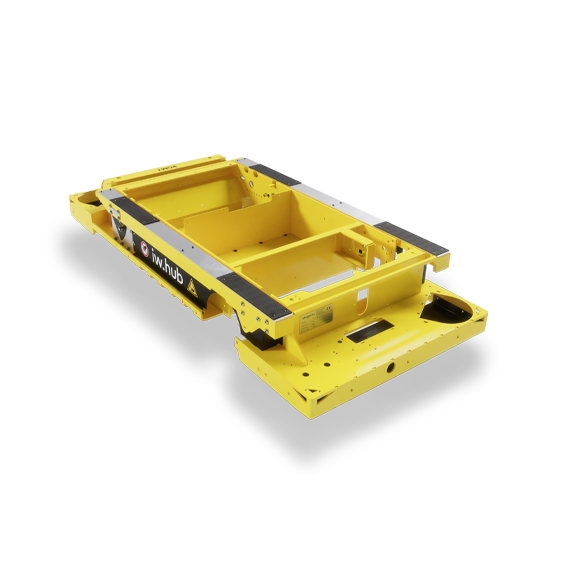

AI on the Edge

GPU-powered Industrial PC (IPC) allowing smart decision-making and AI inference on the edge.

Autonomous Navigation

The autonomous navigation of the iw.hub requires no additional installation or infrastructure. It allows the robot to dynamically adapt to a mixed and dynamic traffic operation, enabling automated processes with limited human supervision.

The iw.hub is equipped with two SICK Microscan 3 Pro LiDars, which means that its safety fields ensure safe navigation around pedestrians, other robots and different assets such as forklifts.

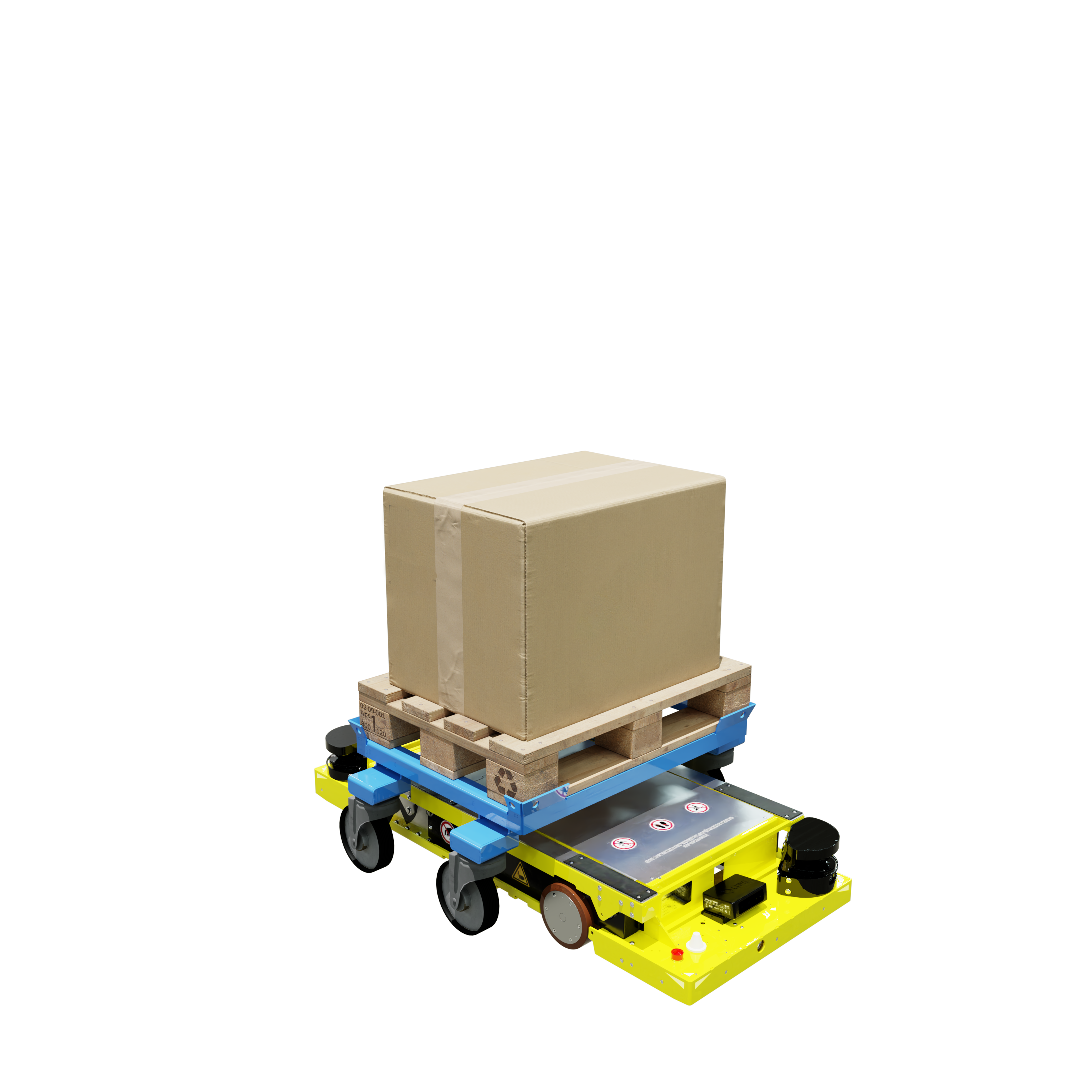

Speed & Load Capacity

With up to 2.2 m/s (4.9 mph) in testing environments, the iw.hub is one of the fastest robots on the market. Its load capacity of 1,000 kg (2,200 lbs) allows the transportation of large and heavy carriers such as steel boxes or pallets.

This fast and agile delivery of heavy loads is enabled by industry-proven hardware and high-quality components.

Smart Decision-Making

AI on edge is enabled by our proprietary industrial PC that is powered by a Nvidia AGX GPU. This allows the iw.hub to quickly and reliably perform complex AI tasks during operations, enabling it to make smart, informed and adaptive decisions in real time based on the information it receives from its surroundings.

Our solution adopts a privacy and ethics-by-design approach, which is crucial in ensuring that these robots operate within ethical and legal boundaries, respecting the privacy of individuals and safeguarding against potential harm.

Hard Facts

Experience the iw.hub yourself

YOur choice

Loading Carriers - Flexible to your needs

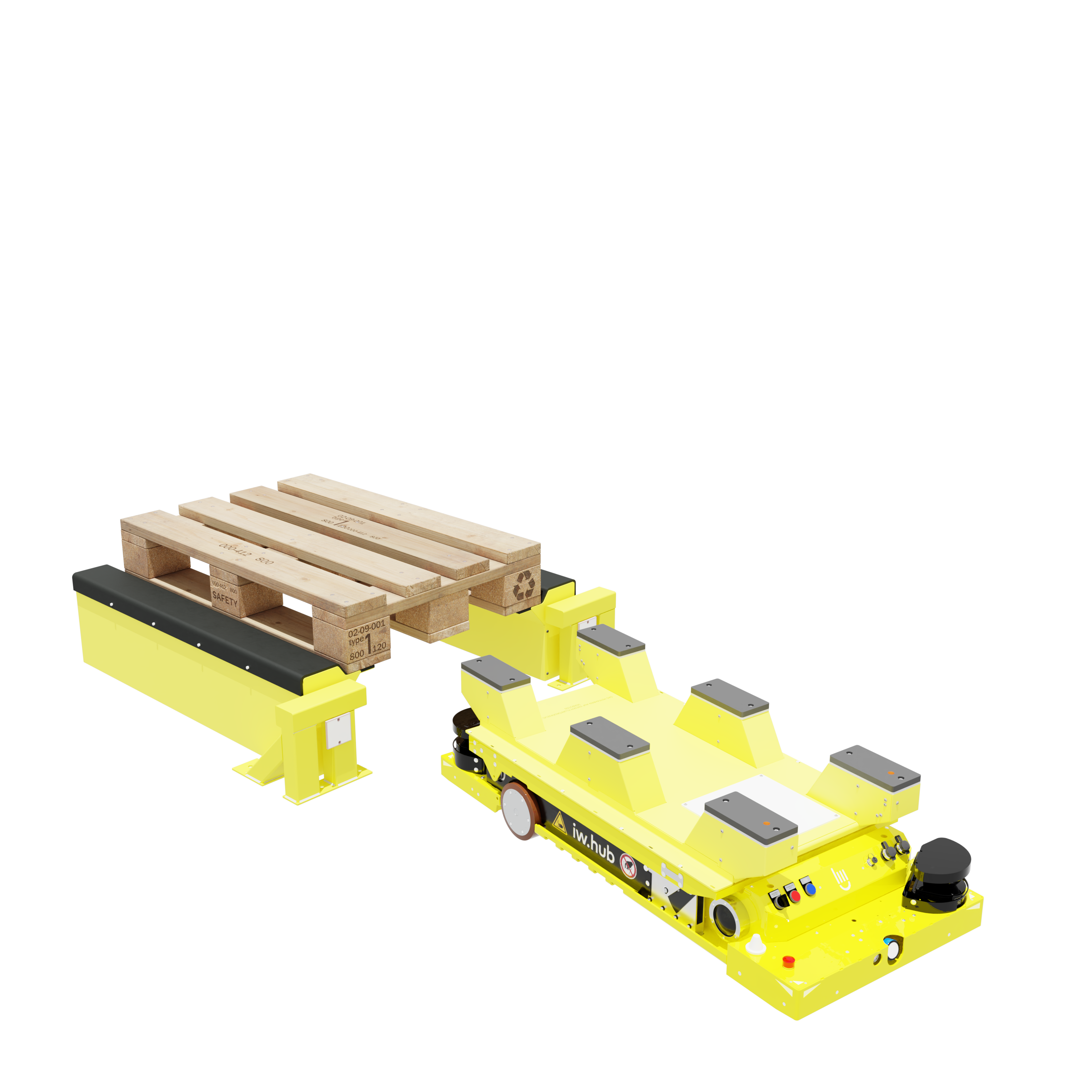

Pallet Dock Solution

Euro Pallet

- High unloading

- L: 1200 mm (47.2")

- W: 800 mm (31.5")

- H: 650 mm (25.6")

Customized Solution

- L: 1200 mm (47.2”)

- W: 800 mm (31.5”)

- H: 420 mm (16.5”)

Euro Pallet

- L: 1200 mm (47.2”)

- W: 800 mm (31.5”)

- H: 280 mm (11“)

Industrial Pallet

- L: 1200 mm (47.2”)

- W: 1000 mm (39.4“)

- H: 340 mm (13.4“)

Düsseldorf Pallet

- Small load carrier

- L: 800 mm (31.5”)

- W: 600 mm (23.6”)

- H: 280 mm (11”)

Customized Rack Solution

- L: 1200 mm (47.2”)

- W: 1000 mm (39.4“)

- H: 1800 mm (70.8”)