‘Synthetic Data: Revolutionizing the Industrial Metaverse’ dives deep into the acceleration of digital transformation through synthetic data, unveiling its potential to reshape industries

Imagine a world where industries can innovate at unprecedented speeds, testing new designs and optimizing processes without the constraints of physical limitations; where cutting-edge platforms like NVIDIA Omniverse are amplifying the capabilities and applications of synthetic data. In our exclusive interview with Jimmy Nassif, CTO of idealworks and co-author of ‘Synthetic Data: Revolutionizing the Industrial Metaverse’, we unravel the groundbreaking insights behind this technology. Jimmy shares first-hand experiences and thoughts on how synthetic data is reshaping industries and fueling digital twin factories.

Jimmy, what inspired you to delve into the topic of synthetic data and its impact on Industry 4.0?

The inspiration stems from a combination of personal experiences, industry trends, and technological advancements. Since Marc Kamradt’s, Joe Tekli’s and my engagement with BMW Group on this subject, we have witnessed first-hand the growing importance of synthetic data in driving innovation within industries. This, coupled with our personal belief in its transformative potential, clearly fueled our exploration. Observing the lack of comparable resources in the market, we felt compelled to contribute our insights by penning a book on the subject. Our aim was to provide a roadmap for others navigating the landscape of synthetic data within Industry 4.0, drawing from our own experiences and research.

I am sensing a strong passion for innovation here.

Absolutely. Our desire to contribute to the understanding of how digital transformation is reshaping industries has been a significant driving force. Through projects like SORDI, we’ve seen the tangible need for synthetic data solutions, further reinforcing our commitment to exploring its impact.

Could you share some insights into the process of researching and writing your book?

The book–writing process was a substantial endeavor, spanning over 1.5 years. It involved meticulous research, drawing from a variety of sources including literature reviews, in-depth analysis of case studies, and consultations with industry experts. Our approach was rooted in practical application, with a focus on real-world examples and specific use cases within companies like BMW Group and idealworks.

Collaboration played a vital role throughout the writing process. Supported by Dirk Dreher, Managing Director BMW Hams Hall Motoren GmbH, and with a foreword written by Rev Lebaredian, VP Omniverse and Simulation Technology at NVIDIA, we pooled our expertise and insights, ensuring that the content was comprehensive and reflective of diverse perspectives. This collaborative effort not only enriched the quality of the book but also facilitated a holistic understanding of the subject matter.

How do you see synthetic data revolutionizing the way industries approach digital transformation and the creation of digital twin factories?

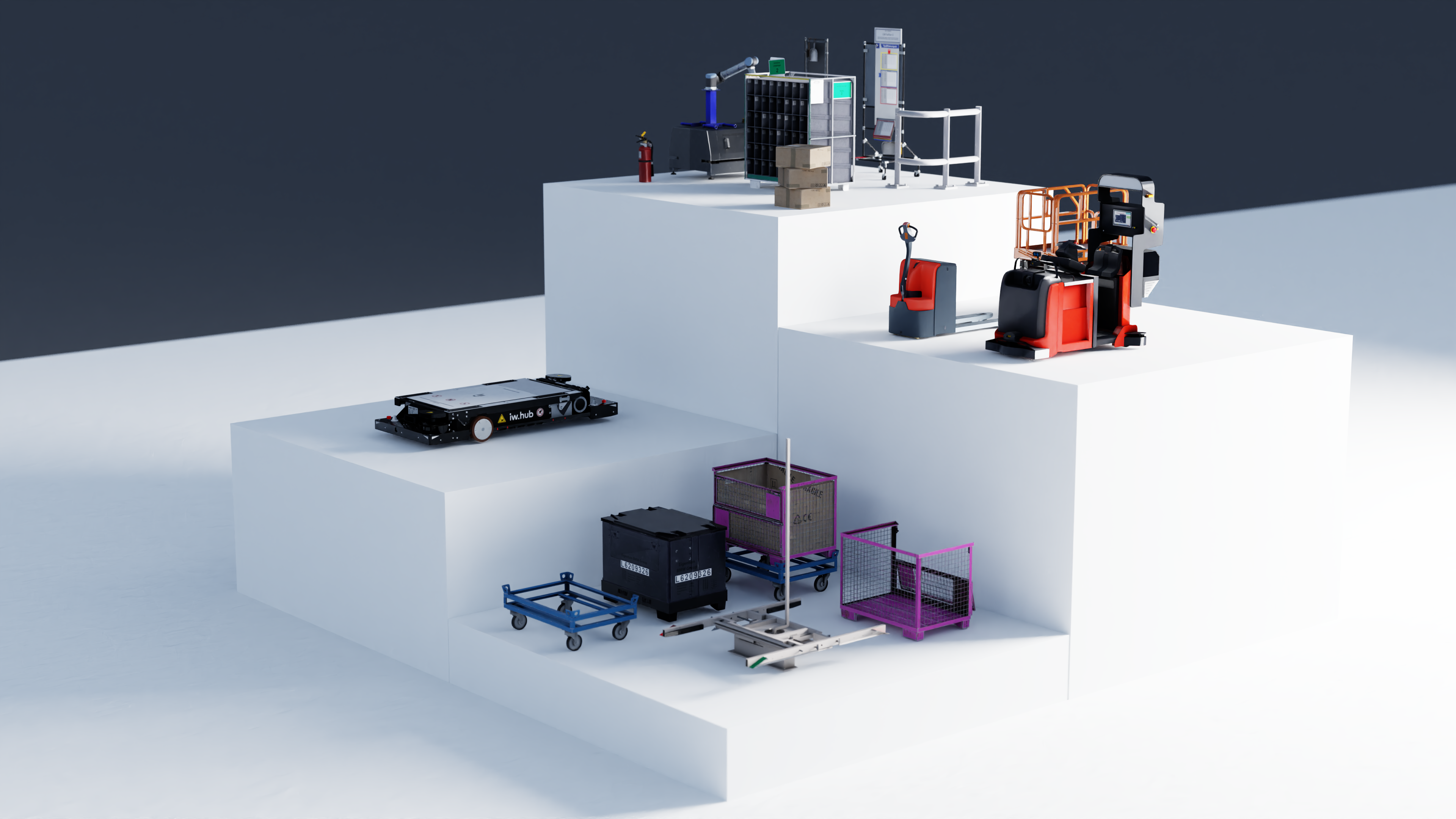

Synthetic data is revolutionizing industries by enabling the creation of virtualized replicas of real-world assets and environments. In the context of industries, synthetic data allows companies to generate virtual replicas of physical assets. These digital twins can be used for various purposes, such as testing new designs, optimizing processes, and even predicting maintenance needs.

Speaking of the beauty of synthetic data...

Which lies in its ability to mimic real-world scenarios with high fidelity, exactly. For example, in manufacturing, companies can use synthetic data to simulate production lines, test new machinery, and optimize workflows before making any physical changes. This not only enhances efficiency but also reduces costs significantly by minimizing the need for physical prototypes and trial-and-error approaches. Synthetic data accelerates innovation by providing companies with a sandbox environment to experiment, iterate quickly, and refine strategies without the constraints and risks associated with real-world implementation, making it a game-changer for digital transformation and the creation of digital twin factories.

Can you elaborate on the role of digitalization technologies in shaping the future of industries?

Digitalization technologies such as AI, IoT, and computer vision are driving the transformation of industries by leveraging data to enhance automation, predictive maintenance, and customization. The interplay between these technologies creates synergies that empower organizations to achieve greater operational efficiency and innovation. For instance, digital twins, powered by synthetic data, provide valuable datasets for training AI models, improving their accuracy and capabilities. As synthetic data becomes increasingly indistinguishable from real data, the reliance on physical data diminishes. The future vision is to transition to a model where 100% of data is synthetic, expanding the possibilities and potential applications in industries.

How do you envision the integration of synthetic data with other technologies like IoT and AI to further enhance industrial processes?

We see a future where synthetic data seamlessly complements these technologies to create more intelligent and responsive industrial systems. With an 80/20 ratio favoring synthetic data as previously mentioned, it plays a crucial role in training AI algorithms, particularly in computer vision applications. For instance, synthetic data can be used to train algorithms to recognize assets, ensure quality assurance, and build digital twins. This extends to robot training in logistics where synthetic data aids in semantic understanding, enabling robots to derive behavior from recognizing assets. Synthetic data enhances the capabilities of IoT and AI by providing high-quality training datasets, driving advancements in predictive maintenance and other industrial processes.

Co-author of ‘Synthetic Data: Revolutionizing the Industrial Metaverse’ and CTO at idealworks, Jimmy Nassif.

In your opinion, what are the most significant benefits that synthetic data offers compared to traditional data sources?

In the context of training computer vision models for industrial applications, synthetic data offers significant advantages over traditional data sources. One of the most notable benefits is scalability; synthetic data can be generated in large volumes much more quickly than collecting real-world data, saving time and resources. Additionally, synthetic data provides diversity by allowing organizations to simulate various scenarios, including aging processes like rust and wear, as seen with SORDI Green. This diversity enhances the robustness of models and their ability to generalize to different conditions. Cost-effectiveness is another key advantage, as generating synthetic data often proves to be more economical than collecting and annotating large volumes of real-world data.

What about human errors?

Synthetic data eliminates human errors and reduces the time-intensive nature of manual data collection and annotation. Generative AI techniques further enhance synthetic data by embedding logic into the generated datasets, such as positioning objects like tables, robots, and pallets in different configurations. In summary, synthetic data enables organizations to overcome the limitations associated with traditional data sources, offering speed, scalability, diversity, and cost-effectiveness while improving the quality and efficiency of computer vision model training for industrial use.

What advice would you give to organizations looking to leverage synthetic data and digital twin technologies to stay competitive in the evolving industrial landscape?

Firstly, invest in building robust data infrastructure capable of handling synthetic data generation and management. This lays the foundation for leveraging the full potential of these technologies. Secondly, foster a culture of innovation within the organization, encouraging teams to explore and experiment with new technologies and methodologies. Thirdly, invest in skills development by training employees to use these technologies effectively.

Having a team well-versed in synthetic data generation, digital twin creation, and AI technologies is crucial for successful implementation and innovation. Collaboration with industry partners can also be beneficial, sharing knowledge and best practices to accelerate the adoption and integration of these technologies. Lastly, recognize the growing importance of digital twins as they are fast becoming a commodity in the industrial landscape. Organizations should act now to incorporate digital twin technologies into their operations to stay ahead of the curve.