Published on March 11, 2024 on industrial-production.de (pp. 11-14)

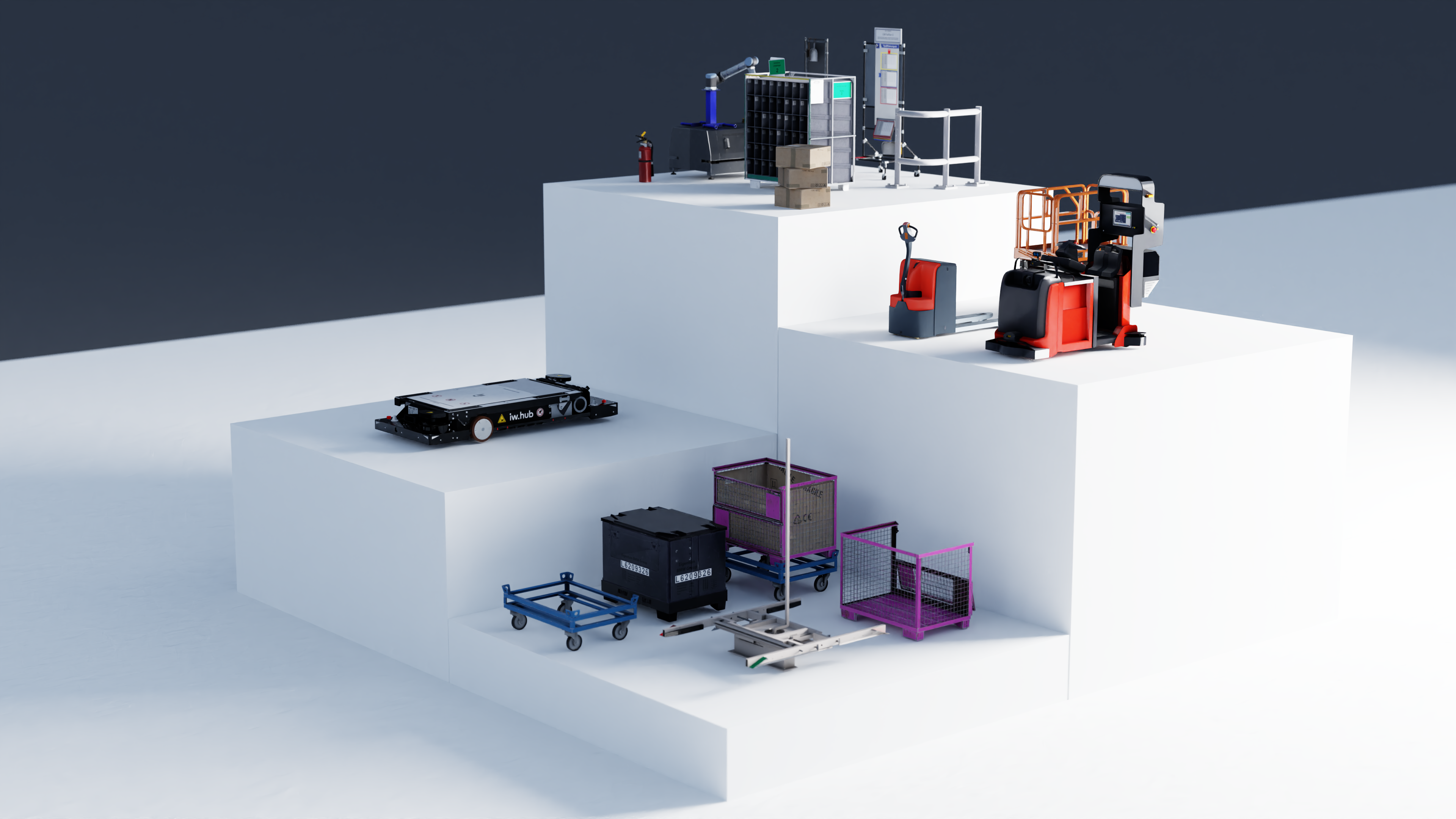

With the combination of a flexible automation platform and mobile robots, idealworks enables the automation of operational processes with seamless integration into existing productions. This creates an entire ecosystem for robotics.

In an era of advanced technologies that define the rules for economic success, idealworks, with the support of BMW, Agile Robots, and other partners, offers an innovative robotics ecosystem for industrial automation.

Fleet Automation With AnyFleet

This consists of the intelligent automation platform AnyFleet and other compatible, independent components. AnyFleet enables the multi-integration of mobile robots via the standardized interface VDA 5050. The modular robotics operating system iw.os empowers mobile robots for autonomy and integrates them directly into AnyFleet.

At the core of the ecosystem concept is the interoperability of mobile robots to centrally manage homogeneous and heterogeneous fleets. For this purpose, AnyFleet connects with IoT devices such as doors, sensors, stations, and traffic lights, as well as with ERP and warehouse management systems. The highly flexible, cloud-based software provides seamless order control, fleet and traffic management, handles complex situations, can be implemented quickly and adapts to the specific requirements of different companies. Seamless integration into existing operations maximizes overall efficiency and leads to significant cost savings.

Alliances with robotics companies such as Sherpa Mobile Robotics, Melkus Mechatronic and Bär Automation bundle expertise, while idealworks also strengthens its position in the field of industrial automation and offers a broad portfolio of solutions. “With the integration into AnyFleet, we can continue to focus on our core competencies in hardware development, while idealworks contributes its strengths in software development,” says Patryk Hoffman, CEO of Melkus Mechatronic, for example.

Successful projects at renowned companies such as BMW Manufacturing, Toyota North America, Zalando, BHS Corrugated, Dräxlmaier, Geis, Purem by Eberspächer and BMW Group underline the efficiency of the robotics ecosystem. The cooperation with the BMW Group is not only a testament to their shared history, but also sets new standards in the automotive industry. With over 700 iw.hubs (AMRs) in operation, the BMW Group is the largest customer of idealworks, which has already established its robotics ecosystem in seven countries in the automotive sector alone

Autonomous Powerhouse iw.hub

CE-certified and equipped with SLAM technology as well as industry-proven hardware and software, the autonomous mobile robot iw.hub navigates safely on its own in mixed traffic. It can navigate around obstacles, avoid people, and autonomously calculate alternative routes. At a speed of 2.2 m/s, it is not only one of the fastest on the market but also handles demanding transportation tasks in highly complex environments with a payload capacity of up to one ton. Thanks to its pallet dock solution, it can flexibly adapt to a wide range of applications.

No adjustments to the existing infrastructure are required for implementing the entire system – neither markers nor magnets or QR codes. Only a power outlet and a Wi-Fi connection are necessary. Milan Nedeljkovic, Member of the Board of Management of BMW AG, Production, says: “With the iw.hub, idealworks offers a unique logistics innovation that has met with a great response and demand within the BMW Group and from customers worldwide.”

Perfection Through simulation

idealworks’ robotics ecosystem goes beyond the realm of physical automation and sets new standards in the virtual world of simulation. While the automation of real processes is an integral part, a variety of customer use cases are optimized in virtual environments, and artificial intelligence is trained in a protected space. As a digital arena, simulation provides the opportunity to perfect routes of autonomous robots and test scenarios before transitioning into physical reality. As a central element of the robotics ecosystem, idealworks’ simulation technology is specifically tailored to the requirements of industrial automation and logistics robotics. Additionally, the method serves as a preventive tool for predicting potential disruptions, leading to minimal downtime and increased overall availability of the robots.

The digital twin, which is a digital replica of a specific space, plays a crucial role. The creation of the digital twin of a customer site allows for the simulation of all scenarios, which not only evaluates the efficiency of logistics but also serves as the key to systematically identifying optimization potential and comprehensive preparation and planning of precise automation solutions.

Scenarios that can occur in real or digital environments are described using a scenario definition language and implemented in the simulation as emulated, accurately replicated use cases. An important function is to fully emulate robot systems and physical sensors, which enables the simulation of real hardware in a virtual space. This allows for the simulation of various situations, including the interaction of iw.hubs, other robots, and their environment.

idealworks uses simulation for internal testing to verify the connection of AnyFleet with physical and simulated iw.hubs, for partner device testing, onboarding of customer hardware, quality control and software validation. Key components such as sensor and iw.os stack emulation ensure precise robot behavior in the simulation, synchronized with the real world. Another advancement is the use of 3D geometry to generate synthetic data for AI models, making complex scenarios such as obstacle avoidance faster, less risky and more efficient.

The extensive use of simulation technology enables idealworks to present innovations in a realistic way, including at events like LogiMAT 2024 in Stuttgart. The focus is not only on technologies but also on practical applications and tangible benefits for the logistics value chain.